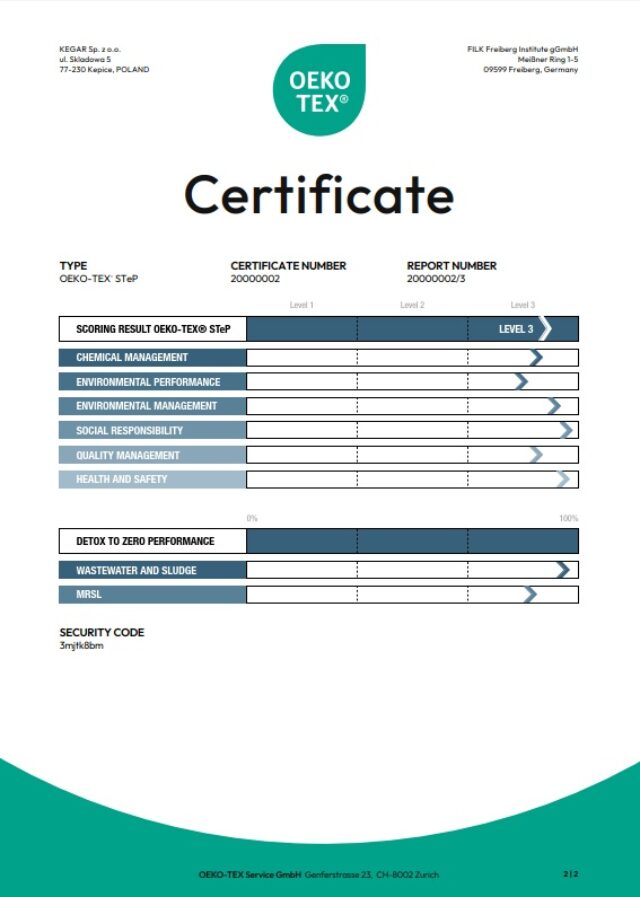

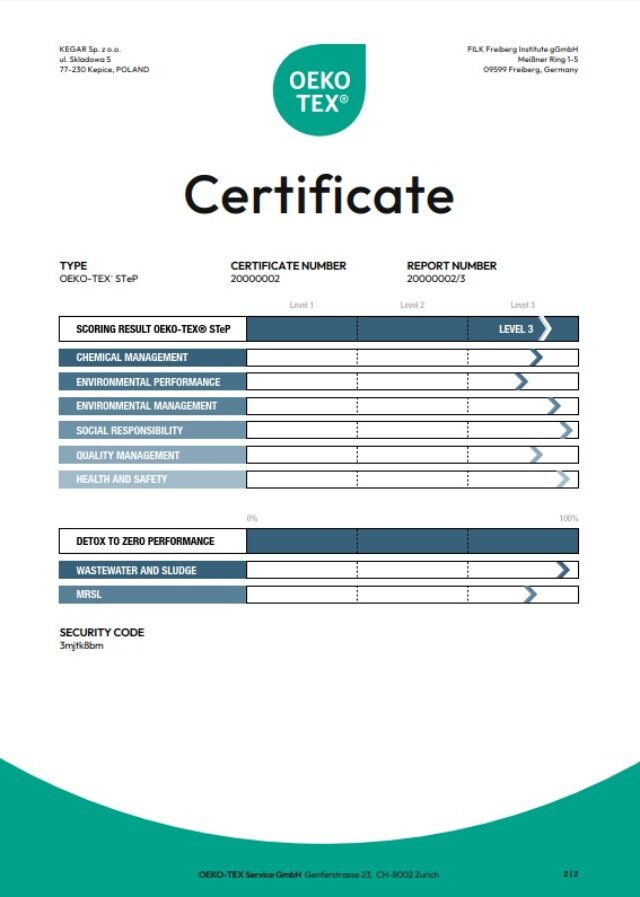

Recertification OEKO-TEX STeP and DETOX TO ZERO

… on June 11, Kegar successfully completes the recertification audit for OEKO-TEX STeP and DETOX TO ZERO.

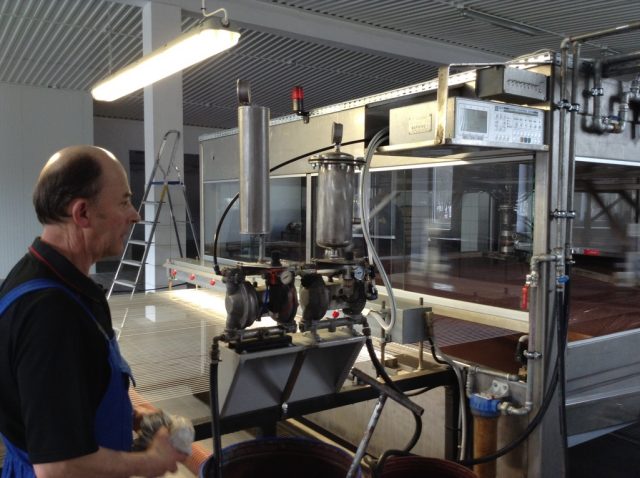

Further modernisation of wet-end department

… April 2025, start of installation works on another 6 retanning drums equipped with an automatic chemical dosing system.

Energy storage

… April 2025, installation of containerized energy storage system (2 x 200 kWh) – action to improve energy efficiency and reduce CO2 emissions.

The installation is currently in test phase.

100% green energy

… since January 2025 all energy purchased by Kegar comes from renewable energy sources – action for sustainable development and CO2 reduction.

LWG certification

… on December 13, Kegar successfully completes the LWG Audit and achives the LWG Approved Subcontractor certificate.

New drums in wet-end department

… in Oktober 2024 the refurbishment of the wet-end department and the installation of 4 new generation retanning drums takes place.

ISO 22301 certification

… on July 26, Kegar obtains an ISO 22301:2020-04 certificate – Business Continuity Management System (BCMS).

0.8 MW solar park

… 2024 the existing solar plant gets expanded with additional 0.2 MW. The total power of the PV installation is now 0.8 MW.

The installation is currently in the the testing phase.

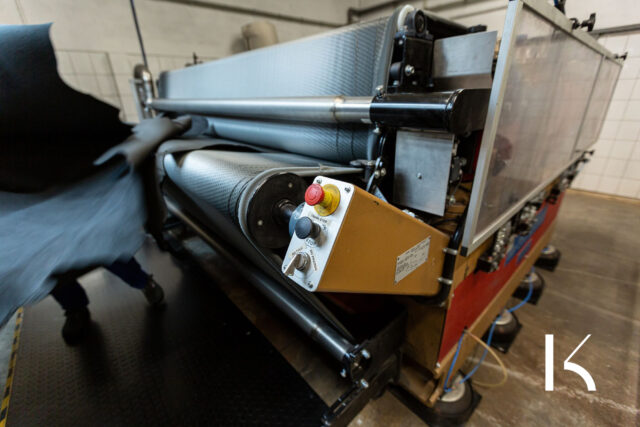

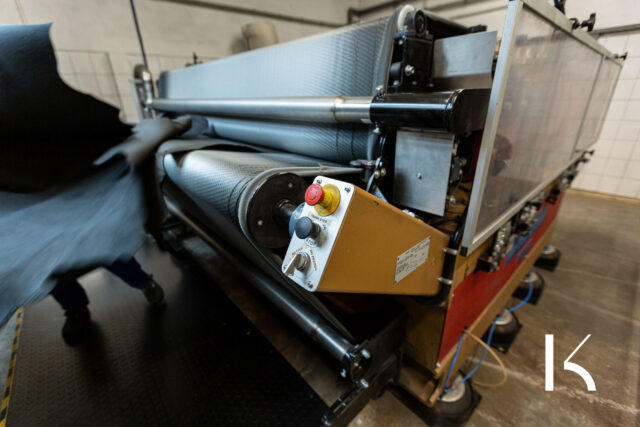

Innovative drying technology

… in January 2024 Kegar installs a new drying tunnel with innovative rafiofrequency drying technology (RF).

OEKO-TEX STeP + DETOX TO ZERO

… on Oktober 25, the compliance audit for OEKO-TEX STeP and DETOX TO ZERO took place.

ISO 9001 & ISO 45001

… in Septmeber 2023 successfull renewal of ISO 9001 and ISO 45001 certificates.

Finishing department 2.0

… in April 2023 the new finishing department started to operate. It is dedicated to the production of light shades.

0,6 MW solar park

… September 2022 completion of the 0,6 MW photovoltaic power station.

STeP by OEKO-TEX®

… on April 27, the STeP by OEKO-TEX® audit was carried out and Kegar has successfully completed the certification process. This modular certification system for production facilities in the textile and leather industry analyses all important areas of a company using 6 modules: chemical management, environmental performance, environmental management, social responsibility, quality management, as well as health protection and safety at work. [13]

Verification of the CO2 Footprint

… since January 2022 Kegar CO2 report are verified by Bureau Veritas – a leading company in testing, inspection and certification.

New generation of the vacuum dryer

… June 2021 a new generation of the vacuum dryer is installed

ISO 45001 certification

… on February 26, Kegar receives the ISO 45001:2018-06 certificate and maintains the ISO 9001:2015-10 certificate.

‘Green‘ administration

… as a part of further measures for the sustainable development photovoltaic panels were installed on the roof of the office building (50kW).

Sustainability – way to go!

… on August 31, 2020 the new carbon footprint report shows a reduction of greenhouse gases …

A new staking machine

… June 2020 a new 4 head staking machine starts to operate

Europe’s coronavirus lockdown

… on March 15, 2020 due to COVID-19 Poland introduced a state of epidemic threat and announced border lockdown.

The whole world is fighting against the COVID-19 pandemic, more and more European countries are announcing lockdown measures.

COVID-19 pandemic

… on December 31, 2019 a new severe acute respiratory syndrome COVID-19 (‘coronavirus’) was first identified in Wuhan in China. The disease is caused by a previously unknown coronavirus SARS-CoV-2.[11]

Greenhouse gases are calculated

…on September 22, 2019 we became our calculation of the carbon footprint for 2018.

The calculation has been made with Ms. Jolanta Baran, Ph. D., Assistant Professor at the Silesian University of Technology, Faculty of Organisation and Management.

SATRA Membership

… Kegar Sp. z o.o. becomes a member of the SATRA community.

ISO 9001 certification

… on October 10, 2017 Kegar is awarded the ISO 9001:2015-10 certificate.

Energy efficiency in the office

… Kegar goes towards ecological sustainability. The new office uses already the modern energy efficient heat pump technology.

A finishing spray line

… on April 3, 2013 a finishing spray line for basecoats is put into service

The drying tunnel arrives

… on May 9, 2012 the inauguration of the new drying tunnel.

Demolition works in full progress

… 2011 the most of the old buildings is demolished, pits filled up and the floors are poured.

An embossing press floats in

… on March 8, 2011 by means of a crane an embossing press ‘Gozzini’ is installed in the finishing department.

Green tannery

… on September 1, 2009 Kegar Sp. z o.o. joins the PCCP (The Polish Cleaner Production Movement Society).

Agreements, agreements, agreements

… on July 1, 2008 another partnership cooperation agreement is signed, this time with Emme Leder GmbH from Switzerland.

Once again Box Calf is produced

… from January 1, 2003 Kegar starts to ship its first Box Calf leather, manufactured according to the Freudenberg standard.

Kegar comes back6

… on December 13, 2002 the company AALCP becomes Kegar Sp. z o. o. again

New partnerships begin

… on December 8, 2002 a parentship cooperation agreement was concluded between Weinheimer Leder GmbH and AALCP Sp. z o. o.

Weinheimer Leder starts

… on December 4, 2002 Weinheimer Leder was founded. The aim is to continue the tradition of Freudenberg Leder.

Freudenberg Leder ceases production

… another big tannery ceases its production. From the September 30, 2002 there is no more tanning in Weinheim by Freudenberg Leder…

The beamhouse rolls up

… on September 28, 2001 the first low-loading vehicles with soaking and tanning drums stand in the yard. The assembling of the beamhouse begins.

Contracts are concluded

… on October 19, 2000 Freudenberg Leder KG and AALCP entered into a 10-year partnership cooperation agreement. It was decided to cooperate in the field of the production of wet-blue and crust leather.