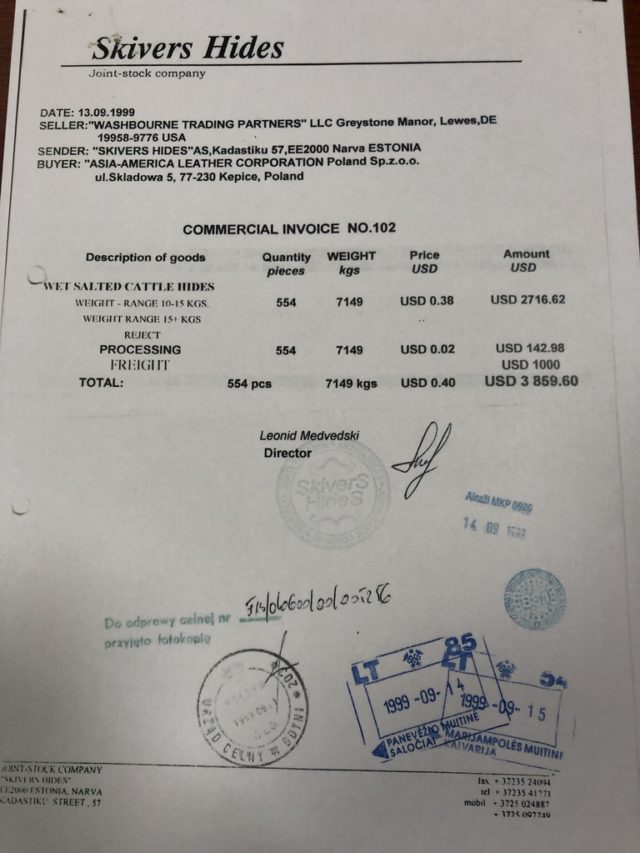

At first only wet-blue

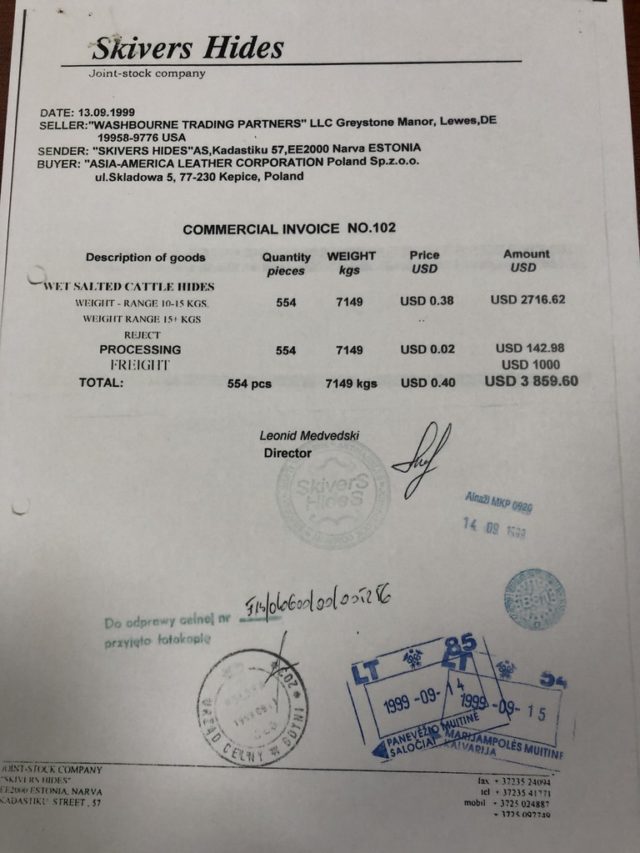

… on September 20, 1999 the first soaking took place. Calfskins, country of origin Estonia.

It goes on again

… on March 31, 1999 AALCP acquires ownership over KZG ‘Kegar’ and parts with the upholstery leather production. The new aim is high quality calf leather.

The end of an era

… July 17, 1998 a black day. KZG ‘Kegar’ ceases production and declares insolvency.

Another transformation comes

… on March 31, 1995 the state-owned company gets transformed into a joint-stock company- KZG Kegar Sp. z o. o.

Kegar is tanning dynamically

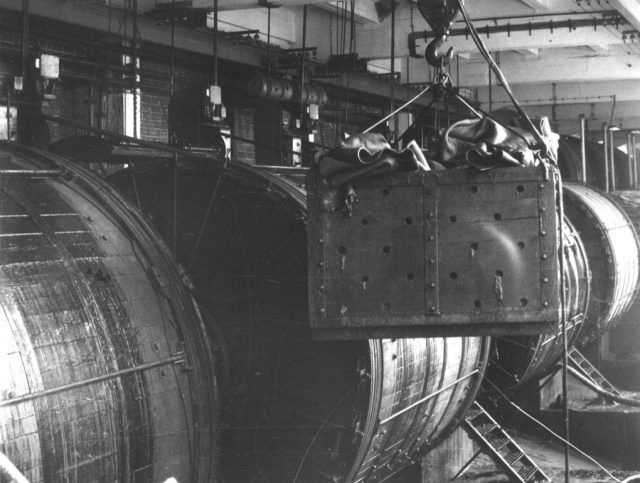

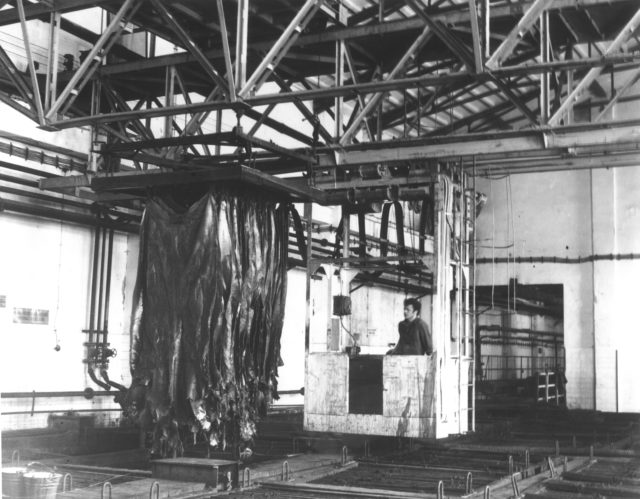

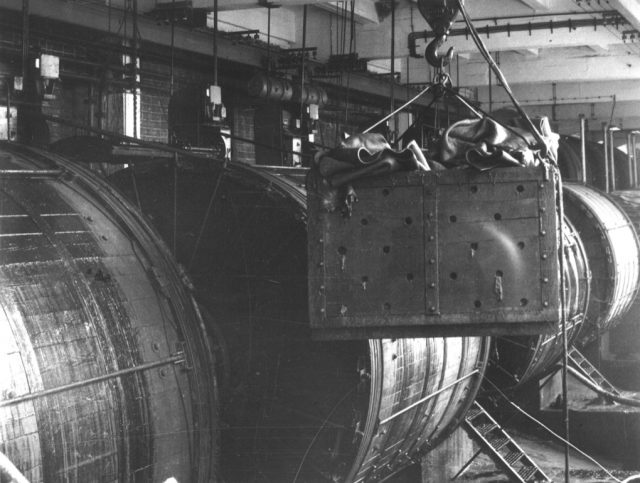

… 1990-1992 fast dynamic leather tanning is introduced. From now on the tanning process takes place in a drum.

Bismarck’s descendants pass away

… on October 1, 1990 Rule von Bismarck passes away without descendants in Chile. He was the last heir of Warcino (Varzin).

The political turn brings changes

… the socially-owned company is transformed into a state-owned Kępickie Zakłady Garbarskie “Kegar”.

Hot pit

… until now the traditional wholly pit tannage cycle took approx. 60-65 days. In 1984 the drying process was modernized and the duration of the hot pit tannage became much shorter. At first the leather was tanned in ‘cold’ liquid and then treated with extracts of max. 40°C / 15-20°Bé. For this purpose the pits had to be heated up. This allowed to reduce the tanning time by one third.

The administration changes its place

… in 1972 the ‘ALKA’ Shoe Factory in Słupsk is established. The management of KZPS is moved to Słupsk. The combined collective company under the name of Północne Zakłady Przemysłu Skórzanego ‘ALKA’ – PZPS ALKA (Northern Leather Industry Company ‘ALKA’) grows further. The tannery from Kępice remains a part of PZPS ALKA until 1989.

From municipality to town rights

… further growth of Kępice. The positive development of the municipality results in receiving of town rights.

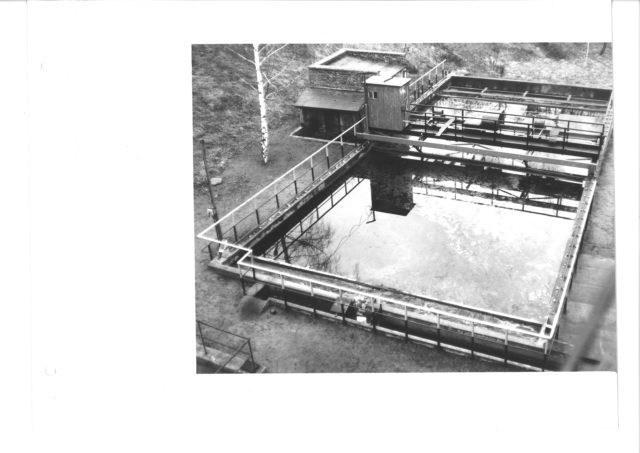

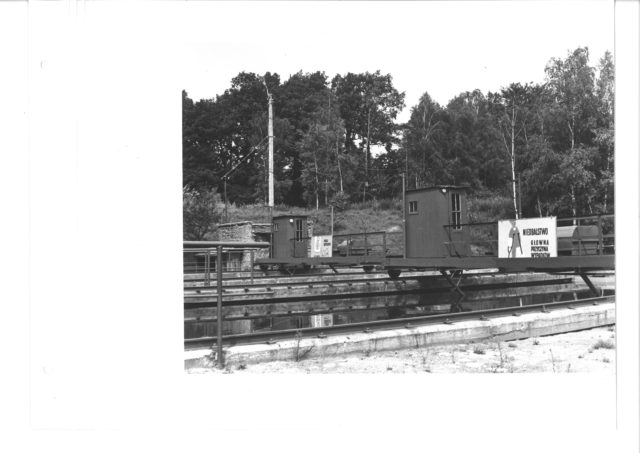

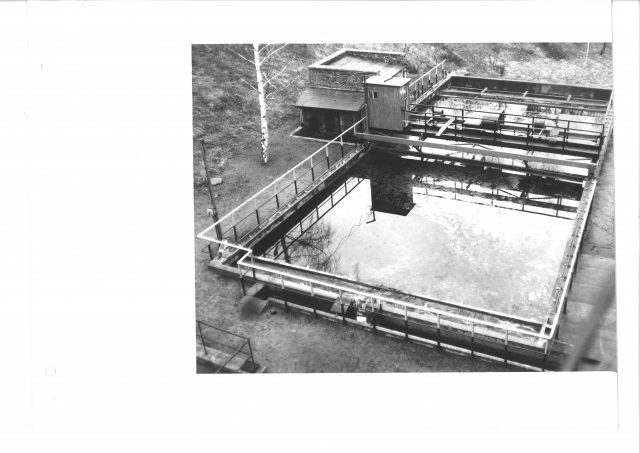

The wastewater treatment plant starts to operate

… 1963/64 the construction works over the wastewater treatment plant to meet the needs of the ongoing production.

A multi-factory leather company

… KZPS – Kępickie Zakłady Przemysłu Skórzanego (Kępice Leather Industry Plant) is established. This multi-factory company encompasses tanneries in Kępice, Dębnica Kaszubska and Białogard, as well as Gloves and Leather Clothing Factory in Miastko

The tannery starts to operate

… on March 9, 1959 the light leather department (P-I) begins its work. Today the production still takes place in the same, fully renovated halls.

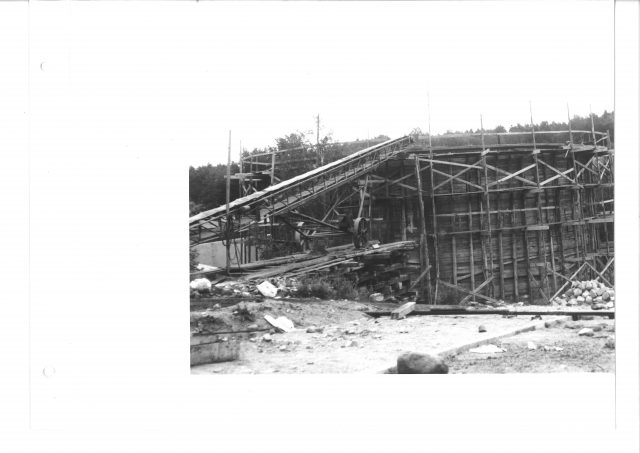

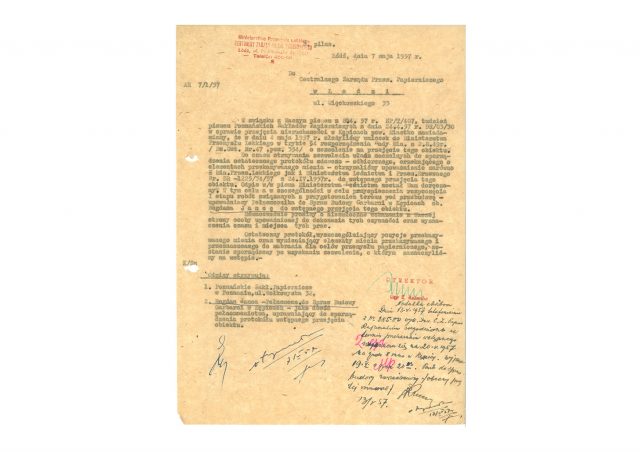

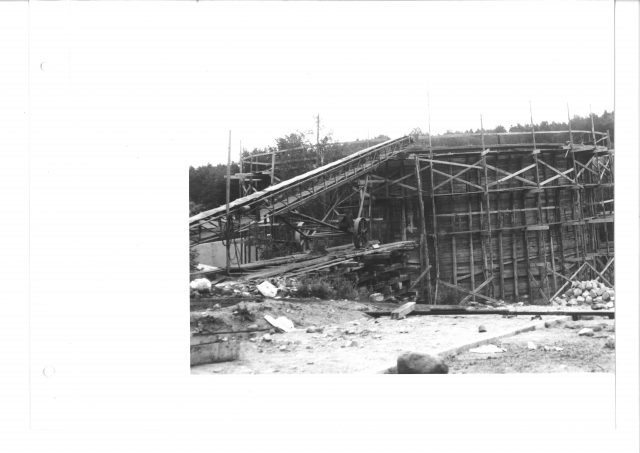

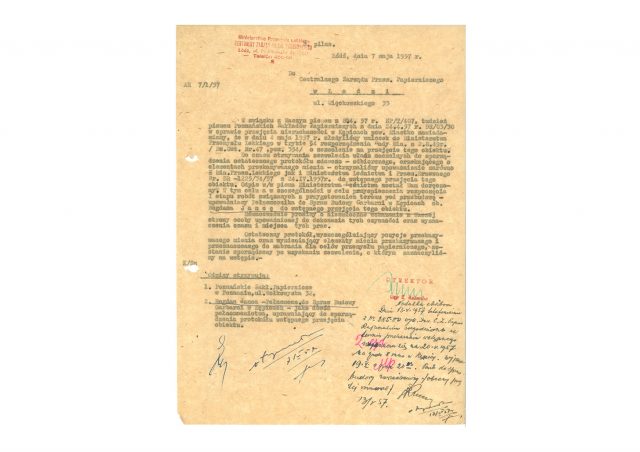

The transformation begins

… on August 29, 1957 the official taking over of the property of ‘Poznańskie Zakłady Papiernicze’ (Poznań Paper Plants) by ‘Kępickie Zakłady Garbarskie w budowie’ (Kepice Tanning Company under construction) takes place. The conversion was conducted by the ‘Bydgoskie Przedsiębiostwo Budownictwa Przemysłowego’ (Bydgoszcz Company of Industrial Construction). The work progress was supervised by engineer Zygmunt Stawiński.

The tanners are coming

… on October 16, 1950 Bogdan Janca, a representative of the Central Board of the Tanning Industry in Poland takes over the factory in Kępice and becomes the first head of ‘Kępickie Zakłady Garbarskie w budowie’ (Kepice Tanning Company under construction).

Everything gets sorted out …

… a primary school is opened. On August 1, 1946 in Bismarck’s estate in Warcino the first Course for Forester Assistant is inaugurated. The craftmanship finds its place and the area begins to develop once again.

Finally the end of the war …

… on March , 1945 the Soviet Red Army liberates Kępice. The paper mill was still in operation until this day. Ultimately, along with the factory in Dębnica Kaszubska it is taken over by the Poznańskie Zakłady Papiernicze’ (Poznań Paper Plants). However, because of the missing machines (war reparations) it was impossible to continue the paper production. Expulsions and forced displacement made the new start even more difficult.

Varziner Papierfabrik grows

… meanwhile the “Varziner Papierfabrik AG” employs as many as 850 people. [2]

Tanning with iron salts appears in discussions and publications

… need is the mother of invention. The scarcity of tanning agents brought own sources forward. Iron slats should have achieved satisfactory results in the tanneries. Jackson and Hou, Jettmar, Stather, Wagner and Päßler und many others researched in this direction. The theory has been extensively described however the practice didn’t bring its superiority over the already known tanning agents.

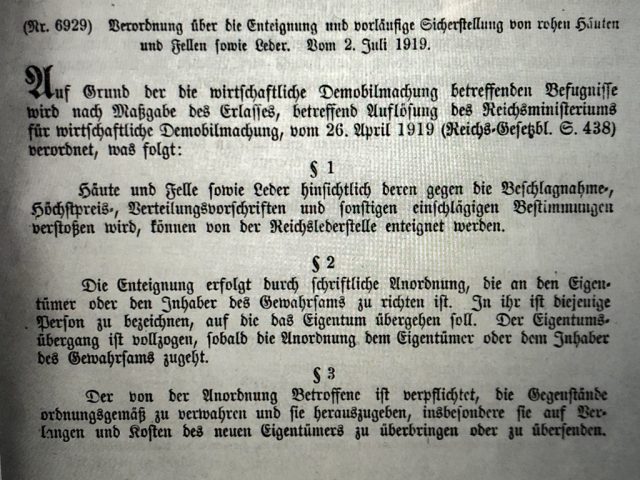

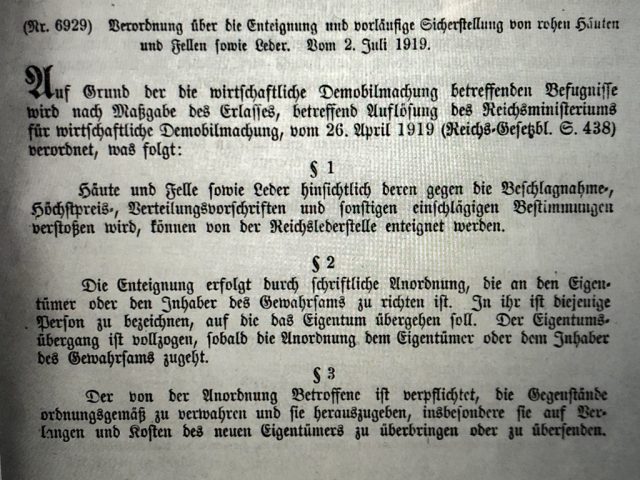

The regulation from July 2, 1919

… §1 – „ Animal skins, hides and leather affecting the rules on confiscation, maximum prices, disposition and other relevant provisions, can be expropriated.”[8]

From the law on expropriation and temporary seizure of animal skins, hides and leather (Gesetz über die Enteignung und vorläufige Sicherstellung von rohen Häuten und Fellen sowie Leder).

Legislative Sejm of 1919

… on January 26, 1919 Piłsudski allows the Sejm elections, which will prepare and pass a democratic constitution. On 20 February, the Small Constitution of 1919 (Mała Konstystucja) was adopted to formally organise the growing state.

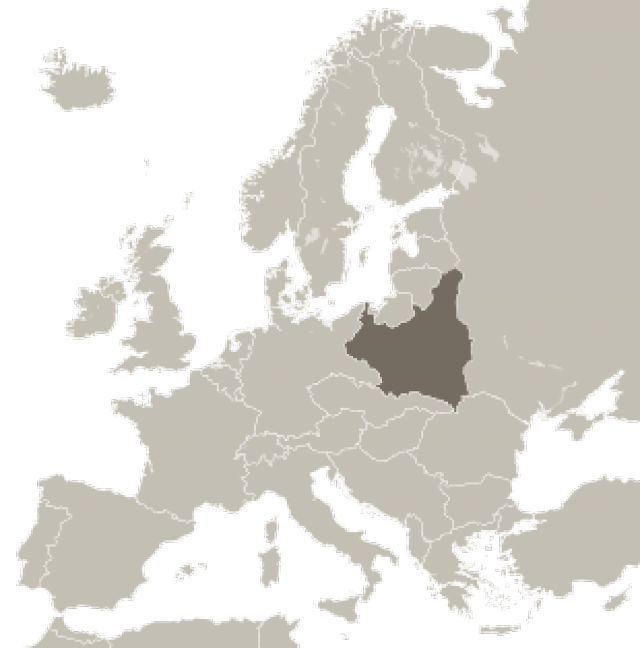

The Second Polish Republic

… on October 7, 1918 the Regency Council in Warsaw proclaimed the Polish independent state. Józef Piłsudski, newly freed from the prison, received the tittle of Provisional Chief of State (Tymczasowy Naczelnik Państwa).

Hydropower stations on Wieprza river

… 4 hydropower plants are built on the river Wieprza (Wipper): Kampmühle (Kępka), Fuchsmühle (Kruszka), Beßwitz (Biesowice), Hammermühle (Kępice).

Further development of Varziner Papierfabrik

… 450 people are already working at Varziner Papierfabrik and it becomes the biggest employer between Kołobrzeg (Kolberg) and Gdańsk (Danzig).[2]

Shoemaking develops on a massive scale

… the new method of making shoes with a cellulose-based adhesive developed by Rampichini offered a possibility to increase the shoe production volume. 10 years later half-boots followed in the footwear fashion.

Modern enzymes brought into action

… so far the animal excrement was used to for the bating process. This was an unhygienic and especially odorous operation.

Dr. Otto Röhm developed the modern bating method using enzymes directly from the pancreases of slaughter cattle. The Röhm & Haas GmbH starts to operate. The commercial product OROPON® enters the tanning industry.

Chrome tannage arrives in Europe

… the chrome tanning method was patented in 1861. Herman Ernst Freudenberg developed the process of tanning with chromium salts. Freudenberg becomes one of the first producers of fine chrome tanned calf leather.

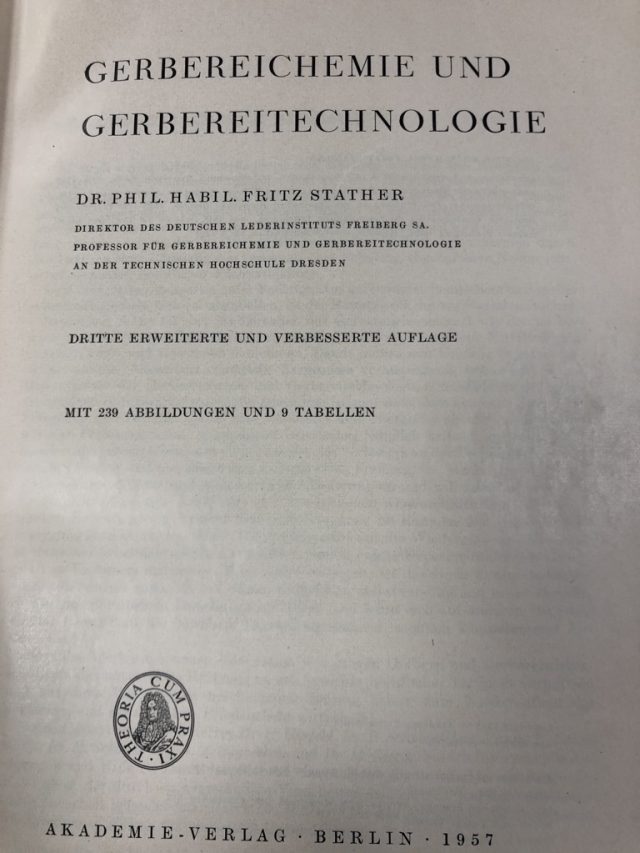

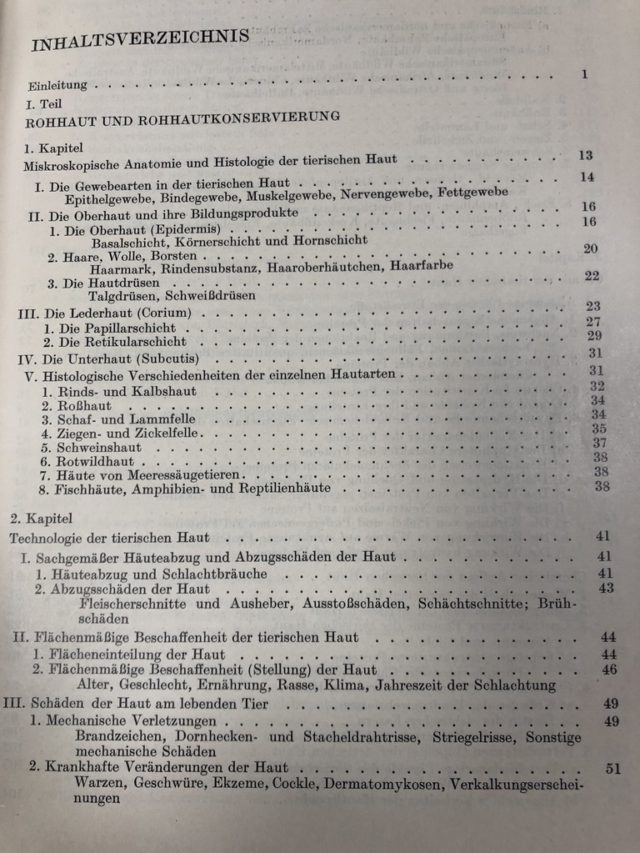

Fritz Stather *

… on November 5, 1901 Fritz Stather was born in Offenburg. From 1930 he was the head of the German Leather Institute in Freiberg. His work ‘Tanning Chemistry and Tanning Technology’ was distributed in 4 editions between 1941 and 1967.[7]

Shoe polish cream captured the market

… the chemist Philipp Adam Schneider developed the first shoe polish cream and patented his invention in the same year.[6]